In this post, I will talk about the insides of the tablet pens I have taken apart (for fun because I had extras). This is not really supposed to be a big topic, however, the post itself ended up becoming pretty long anyways. Whoops.

I am writing this post to give you a little bit of insight into the differences between how each company models their pens, and it will show you why the springiness of some pens feel very different than others (mainly, the difference between Wacom and competitor pens).

If you do not understand how battery-free pens work through EMR, please go Google it as this post will not talk about how EMR technology works.

*Please note that any bad soldering you see on the board was caused by me playing with the solder. All these boards came in perfect condition and they had no issues with how they were originally soldered.

**Also, please don’t try to re-solder anything unless you know what you are doing. I rendered a few of my PW100 pens useless by trying to swap parts between them, even though they were the exact same model.

Wacom LP190K Pen (for Intuos Draw CTL-490)

The first pen I would like to show you is the Wacom LP190K pen, which is the pen for the Wacom Intuos 2015 series (Intuos Draw/Photo/Art/Comic/3D). It is a very basic and simple pen with a plain plastic body, and the inside is just the circuit board and EMR coils.

Since I could not get a good enough grip on the end of the pen to pull it out properly, I resorted to crushing the plastic grip to take the pen apart. In the process, I ended up shattering the metal rod within the coil which is why the coil area is bent in the middle.

There is a metal rod wrapped with a coil at the end, which in turn attaches to the white plastic piece with a rubber stopper. The pen nib goes all the way through the metal rod to the white plastic which holds the pen nib.

The pen nib is held in place by this white plastic part which connects to the rubber stopper. Inside the white plastic part is another smaller metal coil and a plastic contraption which allows slight movement when pressing very hard against the pen nib. The small coil inside the white part moves, while the metal rod and coil outside stay stationary.

This plastic contraption is what gives Wacom’s pens the “Wacom feel”, which is how their pen nibs have very little movement from 0% to 100% pen pressure.

- The pro of this design is that it feels fairly close to how traditional pens/pencils act, which is that their pen tips do not move at all when pressing harder or softer.

- The con of this design is that your small changes in hand pressure result in larger changes in pen pressure. Without practice, the changes in pen pressure will feel hard to control, but that goes for any tablet, really.

This pen costs 30 USD per replacement as given here: Wacom Store

This price seems fair for the effort Wacom has put into the technology inside, but for this model in particular, the amount of effort put into the outside of the pen was very lacking.

Huion PW100 Pen (for Huion H640P, H950P, H1060P, H610Pro V2, etc)

The second pen I would like to show you is the Huion PW100 pen, which is the pen for many Huion tablets including the H640P, H950P, H1060P, and more. It is a nice pen with a wide rubber grip design that is very similar to the Wacom Pro Pen design. The inside consists of the circuit board and EMR contraption held together by a plastic case.

This pen can be pried open by bending the pen back and forth in the middle. Unfortunately, Huion uses glue to hold the two parts together, so sometimes it will take quite a bit of effort to get the two sides apart. I broke the top casing of one pen because it wouldn’t come apart at all, but the other one I was able to take apart without breaking anything.

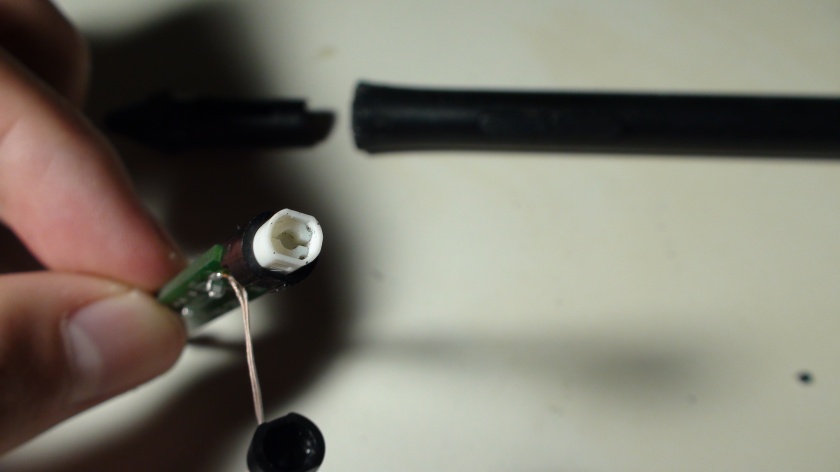

The EMR mechanism for the PW100 uses a moving metal rod within the coil area. You first put in the metal rod, then the rubber stopper, and then the spring. Once those are put in, you screw the white piece into the black circuit board casing, then snap the circuit board into place with the latch on the back of the black plastic casing.

With that, the circuit board section is completely assembled, and all that’s left is to slide it into the bottom half of the pen and it will click into place.

If you feel it getting stuck while sliding it in, make sure not to force it through as you will break the coil cable because that is what is getting caught. Just twist it gently to a different angle and it should slide in easier.

Luckily, the fact that the top part is glued on is not a problem because the circuit board is held in place solely by the latching mechanism in the grip part of the pen.

If the circuit board was held in place by the top half of the pen (as it is in the XP-Pen P05R pen I will show later in this post), then removing the glue on the top part would cause problems where the top piece would not be able to hold the circuit board in place while drawing.

However, since the circuit board is contained in just the grip part of the pen, there are no problems with removing the glue and having a slightly loose top piece.

- The pro of this design is that it is fairly easy to check the inside of your pen if you accidentally let small particles or liquid in. The springiness of the pen nib can also feel more intuitive because the pen nib moves a decent bit from 0% to 100% pen pressure, meaning the pen pressure will be easier to control with slight changes in hand pressure.

- The con of this design is that the pen will not feel like a “traditional” pencil/pen as the pen nib will move and “spring”, in contrast to how the pen tip of a “traditional” pencil/pen does not move at all.

Personally, I find that being able to feel the pen nib move and “spring” is more intuitive for digital art than having the pen nib move very little. It feels like it makes pen pressure control that much easier.

However, this is from my mindset that traditional art is a whole different artform than digital art, and vice versa, so I do not expect digital art to feel like traditional art in the first place, which is why digital art feeling different from traditional art does not bother me at all.

This pen costs 22 USD per replacement as given here: Huion Store

This price seems more than fair as it performs exceptionally well and seems to be quite robust. Honestly, this is a ridiculously low price for a rubber grip pen with seemingly no downsides as far as I can see. It even supports tilt on some models like the H1060P!

Huion PW507 Pen (for Kamvas Pro 12/13)

The third pen I would like to show you is the Huion PW507 pen, which is the pen for the Huion Kamvas Pro 12 and 13. It is nice pen with a wide rubber grip design that is very similar to the Wacom Pro Pen design. The inside consists of the circuit board and EMR contraption held together by a plastic case. It appears to be a variation of the PW100 pen which I mentioned above.

Just like the PW100 pen, the pen can be pried apart at the middle by bending the pen back and forth to loosen the glue.

The EMR mechanism for the PW507 uses the exact same EMR contraption as the PW100, using a moving metal rod within the coil area.

The only difference is that the white plastic area is made of grey plastic, and weirdly enough, you cannot screw the grey plastic part all the way if you want the wires to be able to reach the circuit board while it is snapped into place. I believe this was done purposefully to put less tension on the spring because the PW507 is used on a screen tablet, and you don’t want as much pressure to be put on a thin screen like the Kamvas Pro 13’s fully-laminated screen.

Exactly like the PW100, the PW507 latches into place on the grip piece of the pen using the same dot-to-hole mechanism.

This is a repeat of the previous section, but:

- The pro of this design is that it is fairly easy to check the inside of your pen if you accidentally let small particles or liquid in. The springiness of the pen nib can also feel more intuitive because the pen nib moves a decent bit from 0% to 100% pen pressure, meaning the pen pressure will be easier to control with slight changes in hand pressure.

- The con of this design is that the pen will not feel like a “traditional” pencil/pen as the pen nib will move and “spring”, in contrast to how the pen tip of a “traditional” pencil/pen does not move at all.

This pen costs 50 USD per replacement as given here: Huion Store

This seems like a pretty fair cost… until you realize it uses the exact same parts as the PW100 which is only 22 USD. Please read below for how I can tell they use the exact same parts.

As you may have noticed, the PW507 pen seems to have very similar inner mechanisms to the PW100. Well, the thing is, it’s not just similar, it’s almost completely identical!

The above image shows you 3 circuit boards, 1 taken from the PW507, and 2 taken from the PW100. As you can see, all 3 of them have the exact same code and name on the back, meaning they use the exact same circuit board.

The only difference here is that the PW507 board is tuned to have a slightly different wavelength than the PW100 board. This prevents you from using the PW507 pen with a PW100 tablet, or the PW100 pen with the Kamvas Pro 12/13.

Aside from the different tuning and slightly different length of the coil piece, everything else is identical, from the metal rod, to the coil material, to the spring, rubber stopper, and circuit board. The outer materials and construction, such as the rubber grip and plastic, also do not feel significantly different.

I cannot see any differences that would warrant the 28 USD price difference between the PW100 and PW507.

XP-Pen P05R Pen (for Artist 15.6 Pro)

The fourth pen I would like to show you is the XP-Pen P05R pen, which is the pen for the XP-Pen Artist 15.6 Pro. It is a nice pen with a wide rubber grip design like the Wacom Pro Pen design. The inside consists of the circuit board and EMR contraption, just like the two Huion pens before.

This pen can be pried apart at the middle just like the Huion pens. However, unlike the Huion pens, there is no glue so it is much easier to open without breaking anything.

It appears this pen was made with serviceability in mind as there are bumps which hold the pen together quite tightly, despite the lack of glue. I really like this design which doesn’t depend on glue.

The EMR mechanism for the P05R uses the moving metal rod design, with a metal rod, rubber stopper, and spring inside the plastic coil piece. Unlike the Huion though, this coil piece is attached to the frame with a latching mechanism instead of a screw design.

After latching the coil piece into place, the circuit board is attached to the rest of the frame using a single screw.

I am not sure if this metal backplate on the plastic frame is there for a reason. Maybe it’s there to add extra support for the circuit board? Maybe to prevent outside electrical interference? I have no idea.

For this pen, the top piece of the pen actually holds the circuit board in place, so try not to open the pen too many times, otherwise the top piece may eventually become too loose to hold the circuit board and pen nib in place once the plastic latches become worn down.

If you are using the pen normally and never opening it, there will be no issues with this.

You may have noticed, but the circuit board has UGEE written on it. This is not a cause for any concern because it is officially known that UGEE works with XP-Pen on tablets now after UGEE stopped developing their own tablets.

This is a repeat of the previous section again, but:

- The pro of this design is that it is fairly easy to check the inside of your pen if you accidentally let small particles or liquid in. The springiness of the pen nib can also feel more intuitive because the pen nib moves a decent bit from 0% to 100% pen pressure, meaning the pen pressure will be easier to control with slight changes in hand pressure.

- The con of this design is that the pen will not feel like a “traditional” pencil/pen as the pen nib will move and spring, in contrast to how the pen tip of a “traditional” pencil/pen does not move at all.

This pen costs ?? USD per replacement.

XP-Pen does not offer replacement pens on their official store yet, so I do not know the exact price. However, the other P05 models appear to be 30 USD, so I assume the P05R will probably be around the same price as well. (It’s completely possible that it will be pricier though.)

I cannot speak on the fairness of the price as I do not know the actual price, but as long as it is not way pricier than the standard P05 pen, it will not be “unfair”.

XP-Pen P06 Pen (for Deco 02, Artist 12)

The fifth pen I would like to show you is the XP-Pen P06 pen, which is the pen for the Deco 02 and Artist 12. Or well, I would show you the insides if I could figure out how to open it.

The only spot I could somewhat grip properly was the middle area, but no matter how much I pulled, it would not come apart until I had snapped the circuit board in the middle. If that isn’t the right place to open it from, I have no idea how else to open it, so this is as far as I got with it.

It appears this model has no user serviceability, but I can generally guess that it uses a similar EMR contraption as Wacom’s pens due to the pen nib it uses, and how hard the pen nib feels to push (meaning it does not use the spring design that the other pens do).

But that’s about all I can guess about this pen, really.

Conclusion

I hope this post was somewhat informative to anyone who was interested in seeing the inner workings of some tablet pens. This post kind of also works as the explanation as to why Wacom pens have a different feel compared to other companies, which is because Wacom doesn’t use springs in their pens.

Just as a side note, please don’t start going around opening your pens unless you absolutely need to. More often than not, you will break something when opening it making it unusable, so unless you are just playing with extras, please don’t take that risk.

Thank you for taking your time writing such detailed post! My Huion PW100 Pen had a “draw while hovering issue”, so I followed your post and dissemble my pen until the end, and guess what? My metal rod shockingly has broken into half! That explains why I have the hovering issue after dropping the pen.

Now I am stuck at assembling the metal rod part. Regarding the photo that showed metal rod, spring and a stopper, am I doing it the right way? (https://imgur.com/ZJ1DBtu)

LikeLike

Hey there, I’m sorry to hear about the broken metal rod!

With regards to putting it back together, you have the parts in the right order. You first put in the metal rod, then the rubber stopper with the flat side facing the metal rod, then the spring will fit onto the rubber stopper. You then screw it onto the plastic frame and clip the PCB into place.

LikeLike

Thank you for the detailed steps. It seems to fit correctly now! Well, though I don’t have the tools to glue the metal rod together just yet, the pen now consistently shows the maximum pressure points (8192) whenever I land on the tablet xD. But still definitely better than the hovering issue.

LikeLike

Personally, I have a feeling that gluing the metal rod together won’t fix the problem, but I guess it doesn’t hurt to try. Tell me how it goes when you try it!

LikeLike

Well, I don’t have the right material for the job to begin with so I will just tell you the process even though it is futile and dumb.

1st attempt – tried assembling but with the broken metal rod -> end up getting constant 8192 pressure.

2nd attempt – tried sticking the metal rod with a cellophane tape as thin as possible -> rod unable to fit the tube.

3rd attempt – stick the metal rod with a non sticky glue -> Pressure point now varies but shows hovering issue. (Tested using sensitivity adjustment=0.

From the beginning, I was lucky enough to not break a single thing thanks to your picture reference. Unfortunately, at the end of the day, while tightening the tube, I accidentally snap the cable which simply means game over. No tools to solder let alone the experience. There you go, a futile yet desperate attempt to save a broken pen.

(The bubble wrapped pen is another Huion PW100 replacement pen. Just to increase resistance to drops xD)

https://imgur.com/LrrusrU

LikeLike

“a futile yet desperate attempt to save a broken pen.”

That made me laugh pretty good! Thanks for sharing that experience x)

LikeLike

Came to this post as it was the only thing I could find that showed the newer battery-free Huion PW100 pen disassembled. The pictures and detailed description helped a great deal, and thanks to your warning , I managed to open the outer casing without breaking it! To my dismay, the green coil glue wasn’t just in the middle of the coil in my pen, it was poured directly over where the two wires meet the plastic that holds the circuit board. I had to painstakingly prod at the glue in order to gently release the wires without snapping them so that I could then reach the inner spring mechanism.

I discovered the metal rod in my pen had also split right in half. I know that the glue didn’t seem to work for the previous commenter, and since I do have a soldering iron, I’ll probably give that a shot. I want to try maybe a little piece of aluminum foil or something less permanent before, just in case. I’ll try to report back if I manage to make it work again!

LikeLiked by 1 person

Hey, the metal rod in my PW500 snapped in half. Did anyone have succes with soldering it back together?

LikeLike

Which tablet or brand do you think have the best pen in terms of performance, functionality and design? Pro Pen 2 seems to overpriced for a replacement despite the high praises

LikeLike

Hey there, that’s a good question.

Personally, I like the Huion PW100 pen the most because it’s simple, cheap, and performs extremely well if the tablet makes use of its capabilities properly (like how the Huion H1060P uses it).

I also like how it’s made in a way where the whole PCB and pen nib mechanism is properly locked into place in the grip portion of the pen and doesn’t depend on the top piece to keep itself in place. This ensures that it won’t move around, even if the top part of the pen is loose.

Since I had so many PW100 pens at one point, I also did an informal durability test at one point where I dropped them from 1m up onto the floor, and threw them lightly at the wall. None of them broke from those tests, and only when I dropped them directly on the pen nib did they start losing portions of their pen pressure. Those tests really boosted my confidence about the PW100 pens durability.

I also like how the XP-Pen P05 pen performs, but I’m really not sold on the way it uses the top part of the pen to hold the PCB and pen nib mechanism in place. I imagine the whole PCB and pen nib mechanism will be unusable if the top part becomes loose.

I also haven’t really seen the P05 perform to its max potential because XP-Pen still hasn’t fixed the pen tapering issue in their drivers. Perhaps if they fix the pen tapering, I’ll come to like the P05 more.

Oh, speaking of XP-Pen, I really liked the new PA1 pen that was used on the XP-Pen Deco Pro. The surprising thing about it was that it doesn’t let the pen nib rotate which really helps with flat pen nibs because they won’t roll over their flat sides that way. The PA1 also had pretty good pen tilt sensitivity, compared to the P05R on the XP-Pen Artist 15.6 Pro which had horrendous pen tilt sensitivity.

The PA1 is pretty cheap too (only 18 USD), so maybe I should buy a replacement and rip it ope- I mean, see what it looks like inside. How tempting.

-Nikage

LikeLike

Hi! I have a PW507 with a puncture mark from where my dog chewed just above the nib, and now my pen is registering lines on/off, do you think there’s any way to fix this myself or should I order a new pen? If the coiled part was punctured, do you know of any way to fix it?

LikeLike

Hi there,

Unfortunately, I do not know how to fix the parts if they are damaged. All I know is how to swap the parts between the pens and put them back together. You can certainly try fixing it yourself, but I never had any luck fixing any broken parts myself.

You could also try messaging Huion support to see if they’d be willing to do anything for you, but I doubt they will offer a free replacement if the damage was caused by your dog so you will probably need to buy a new pen in the end.

As a side note, you should try looking up the replacement pen on Amazon since it’s often cheaper there. The official huiontablet.com store is often quite a bit pricier due to shipping, so it should only be your last choice for buying the replacement pen.

Sorry I can be of more help,

Nikage

LikeLike

Hey there.

Does the PW500, PW507 and PW100 pen have any noticeable difference apart from its colors or on-paper specifications and prices?

I often wonder why does the PW507 pen is used for the smaller-sized Kamvas tablets, while PW500 is used for the larger ones. Interestingly, the “higher-end” screenless tablets like Q11K V2, WH1409 V2 and upcoming Inspiroy Dial uses the PW500 like the more expensive Kamvas series.

LikeLike

Hey there,

As far as I can tell, no, they do not have noticeable differences apart from their colours and prices.

Aside from the obvious differences, they use different “frequencies” to communicate with the tablet, so you can’t use the PW100 on a PW500/507 tablet, and vice versa. The PW500 also does not work on a PW507 tablet (despite looking so similar), and vice versa.

I can’t really make any assumptions about why the PW500/507 is so much more expensive than the PW100. They could honestly have some kind of design differences which make the PW500/507 harder to make.

However, from what I’ve experienced personally, I can’t tell the difference between them at all and the price difference just feels unnecessary. The PW100 and PW500/507 works the same for me, and the PW100 even feels better to draw with sometimes.

-Nikage

LikeLike

What makes the PW100 better? Tho that’s quite a shame, especially after seeing your experiment that the inner components of those pens are likely similar. I’d like to think they are priced higher because they’re bundled with the more premium tablets but if only there were slight difference than just that. I also just noticed that the older Huion Kamvas 20 uses the PW500, but the 2019 edition uses the PW507? Maybe I’m overthinking but that’s a interesting change considering PW507 is 10$ cheaper than PW500 on Amazon. That is why I needed to know what else are the differences.

At least it’s better than Wacom giving a pen that’s literally a stick of plastic to the Intuos series just to make the Pro Pen 2 feels superior I guess.

LikeLike

Hey again,

For me, I liked the PW100 more than the PW507 because the springiness of the pen nib was harder on the PW100, so it’s not that it’s objectively better, it’s just that I liked the feel of drawing with the PW100 a bit more.

Yeah, the situation which you pointed out about the Huion Kamvas 20 is quite odd and I have no idea why they are switching the pens. If I was a bit more knowledgeable about electronics, I would try to find the difference, but unfortunately, I know almost nothing about the details of how the hardware works.

Haha true, it’s great that Huion offers decent pens for both the low-end and high-end options.

-Nikage

LikeLike

Well, any guesses about why Inspiroy Dial uses PW500 pen instead of PW100 ? (even though it’s actually a pen tab and not a Display Tablet that need reduced amount of applied Pressure ?)

LikeLike

Well, it seems they’ve also been using the same PW500 with Huion Q11K V2, instead of PW100… Does it have to do with the less springyness (and tension)… Well, I’m speechless now..

LikeLike

In my honest opinion, the PW500/507 appears to be what Huion considers to be their “premium” pen series because it is paired with their higher priced models.

I can’t see why they chose to use it for the screen-less tablets either though since opening up the pen showed no noticeable difference from the cheaper PW100 series, and only the springiness of the pen is different which, like you said, shouldn’t matter for screen-less tablets.

LikeLike

hi, i would like to know are the metal rod in PW 100 is the same as the one in PW507

i broke mine in half and causing hovering issue

i’m planing to buy pw100 because it’s cheaper and make the metal rod as a donor for my PW507

and thank you for the post, it help me figuring what’s wrong with my pen

LikeLike

Hey there,

That’s an interesting idea!

I don’t have any more extra PW507 pens which I can risk taking apart and the PW507 which I did take apart has already been ruined by me trying to resolder it, so I can’t directly confirm that switching the metal rods works.

However, I vaguely recall that I previously tried swapping around the metal rods, but my pens ended up perpetually right-clicking or holding down left click and not working properly. So from what I can see, the electrical signal of each pen might be tuned to match their components, and switching around parts between pens will cause that signal to change and not match the signal that the tablet is looking for.

If you have an extra 20 dollars lying around, then maybe you can give it a try. However, I don’t think that using a PW100 pen metal rod as a donor will work. The PW100 and PW500 metal rods do look almost the exact same, but I believe they may actually be different enough to cause issues.

-Nikage

LikeLiked by 1 person

Ah i see, thanks for the info about the metal rod

i will try to do the donor and try to tweak it, maybe it will work or maybe not

i’ll be in luck if the donor methods work for me, who knows?

thank you again for everything

cheers!!!

LikeLike

Thanks so much for these pics and details! I’ve been wondering about this when thinking of addressing my Kamvas Pro 13’s tilt offset issue. After seeing your pics, I know I don’t want to risk breaking the pen to get inside. If their new firmware doesn’t help, I may slightly sand down the nib and surrounding tip. It drives me crazy to have the cursor drift with my tilt, even if its just a few mm.

Years ago, when Cintiqs were thousands, I spent some time trying to build one with old Wacom tablets and laptop screens. I got pretty close and learned a lot, and can guess some answers to some questions.

The PW100 circuit board has an added potentiometer soldered in there. I assume it adjusts frequency, it looks very similar to a Wacom Intuos3 setup. I was once able to reduce some jitter by tuning this screw. It might add a bit of labor for tuning, but as you said, no reason for such a price increase.

I had to try a lot of combinations to find a screen that didn’t cause too much interference with my tablet, and different tablet generations needed different screens. This may be why Huion uses so many different pens depending on screen. Until the newest generation, it looks as if they’ve been adapting older drawing tablet tech to work with different panels, instead of developing the pen/tablet for the screen first. I could be wrong, it’s just the impression I get, especially given how quickly Huion is growing.

I got the PW507 for 43 bux shipped from Huion’s ebay site. I agree the higher prices are inflated by being a ‘premium’ product. They probably manufacture a lot more PW100’s though.

Thanks again for all your effort here, keep tinkering.

LikeLike

I did something with my pen and I need some help, for those that will try to help me send me an email, nicolaslobo9@gmail.com

it’s about a LP190K pen, I need to disassemble it, for fixing.

LikeLike

Thank you for this great article, just fixed my PW100, which I bought a month ago as a replacement for another PW100 that broke down earlier. With two broken pens I was finally angry enough to test your solution 🙂

I hope my clumsy soldering will make it work for a little longer than the one from the factory.

LikeLike

Hey

first of all thank you for this post!

The tip and the buttons of my LP190K are wobbly and I want to replace the tactile switches.

SMD soldering is no problem for me.

Quick question: are the front and back parts of the glued into the body or are they just pressed into it?

Might be going in from the back end be a better idea than from the front end (no pun intended)?

regards

LikeLike

Hi there,

I took a closer look at the front and back ends of the plastic casing and it appears that there may have been some glue involved as there is some yellow residue. It’s a bit hard to see even when I look closely because of how badly I crushed it to take it apart.

I also checked just now, but I failed to mention that the PCB is held in place inside the plastic body with a cutout slot inside the tube. This means that it can only be pulled out towards the front and cannot be slid out from the back end (if you were to cut off the top of the back end). As such, I do not think going in from the back is an option.

I will also admit that I have attempted some resoldering of parts, but have never been able to successfully use the resoldered pens with a tablet again. I believe these circuits are very sensitive to slight differences in their voltages, so even just slightly moving the coil or changing the resistance results in the tablet not reading the right pressure levels.

I’m all for you giving resoldering a shot, but I hope you will keep in mind that there is a high chance the pen may not work the same afterwards. Although if you’re good at characterizing circuits, then perhaps you can figure out the exact voltages and how to adjust the circuit to match.

-Nikage

LikeLike

Thanks for this post. Very Informative.

LikeLike

Thank you for this article. I found this article while searching for issue with my Huion PW100 pen hovering issue. My PW100 had broken metal rods. Instead of PW100 for ~$20, I bought HUION H420X OSU ( which include PW100) for $20 from ebay. I just wanted to say thank you for your article.

LikeLike